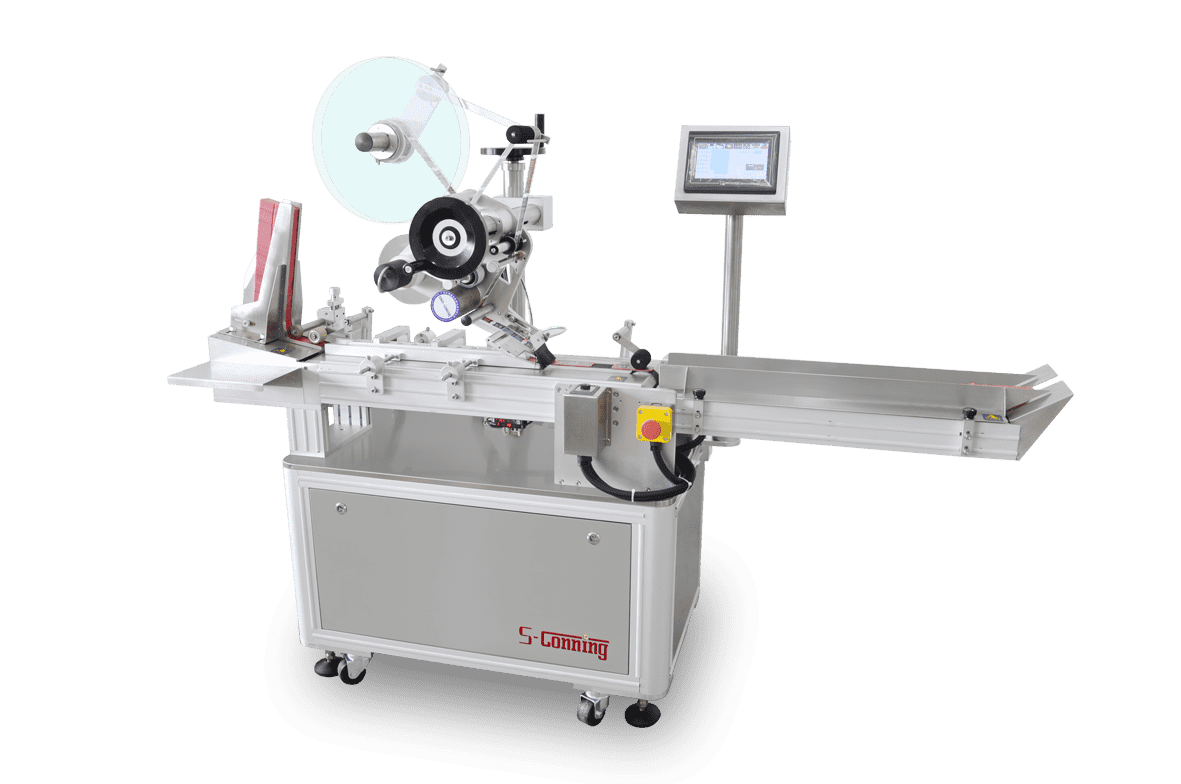

Reliable Supplier Automated Tube Labeling System - S820 Double side labeler – S-conning Detail:

S820 Double side labeler

S820 is front and back labeling on oval or rectangular shaped containers in the daily chemical, food and beverage, pharmaceutical and others industries. ensuring consistent labeling bottles into the right front stance; the Special elastic top belt adjustment device, so that the replacement of different size bottles of operation more simple and convenient Both Stand -alone and online operation,Adding option mechanism, labeling on both round bottle and flat bottles will be done with one machine.

• Humanized touch screen: Simple and direct operation, complete functions and rich online help functions.

• Double chain with calibration device to ensure the neutrality of flat and square bottles.

• The special elastic jacking belt device is hard synchronous with the main conveyor belt to ensure the vertical stability of bottle body pressing and conveying.

• optional transparent label detection electric eye to improve the detection accuracy.

• Label parameter storage function (you can pre-store 50 groups of label parameters), no need to reset when changing the bottle.

• It can be equipped with devices such as coil sticking and positioning to achieve more labeling requirements of bottle shape (including coil sticking).

• Provide a variety of detection functions, such as label labeling detection, code leakage detection and printing content detection;Substandard bottles will be removed for recycling.

• can be equipped with hot stamping machine, heat transfer printer or inkjet printer synchronous code typing and labeling.

• Intelligent label management function, warning prompt function, optional image detection system, etc.

| S/No. | Item | Parameters | Remark |

| 1 | Speed | Flat bottle≦200 botles/minute | Related to the Bottle size, Label Size and feed speed |

| 2 | Bottle Size | Flat bottleThickness: 20-90mm; Height≦300mm | |

| 3 | Labeling Accuracy | ±1.5mm | Not including error of the paste & label |

| 4 | Stop label Accuracy | ±0.3mm | |

| 5 | Conveyor speed | 5~40meters/minute | |

| 6 | Speed of label sending out | 3~50meters/minute | |

| 7 | Width of Conveyor belt | 91mm | |

| 8 | Label roll | inner diameter:76mm, outer diameter:350mm | |

| 9 | Power | 220V±5% 50/60Hz 1KW | |

| 10 | Direction | tight→left or left→right(Determine your direction when placing an order) | “Direction” refers to the direction of object flow when the worker is facing the operating interface |

| 11 | Machine Outer Size (mm) | About(L)3000mm ×(W)1650mm × (H)1500mm | For reference only. Please confirm the size of the final plan |

Product detail pictures:

Related Product Guide:

Our purpose would be to offer good quality products at competitive price ranges, and top-notch support to clients around the whole world. We're ISO9001, CE, and GS certified and strictly adhere to their good quality specifications for Reliable Supplier Automated Tube Labeling System - S820 Double side labeler – S-conning , The product will supply to all over the world, such as: Comoros, Frankfurt, Buenos Aires, We have a excellent team supplying professional service, prompt reply, timely delivery, excellent quality and best price to our customers. Satisfaction and good credit to every customer is our priority. We are sincerely looking forward to cooperate with customers all over the world. We believe we can satisfy with you. We also warmly welcome customers to visit our company and purchase our products.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!