Good Quality Pharmaceutical Machinery - S308 High speed rotary vial labeling machine – S-conning Detail:

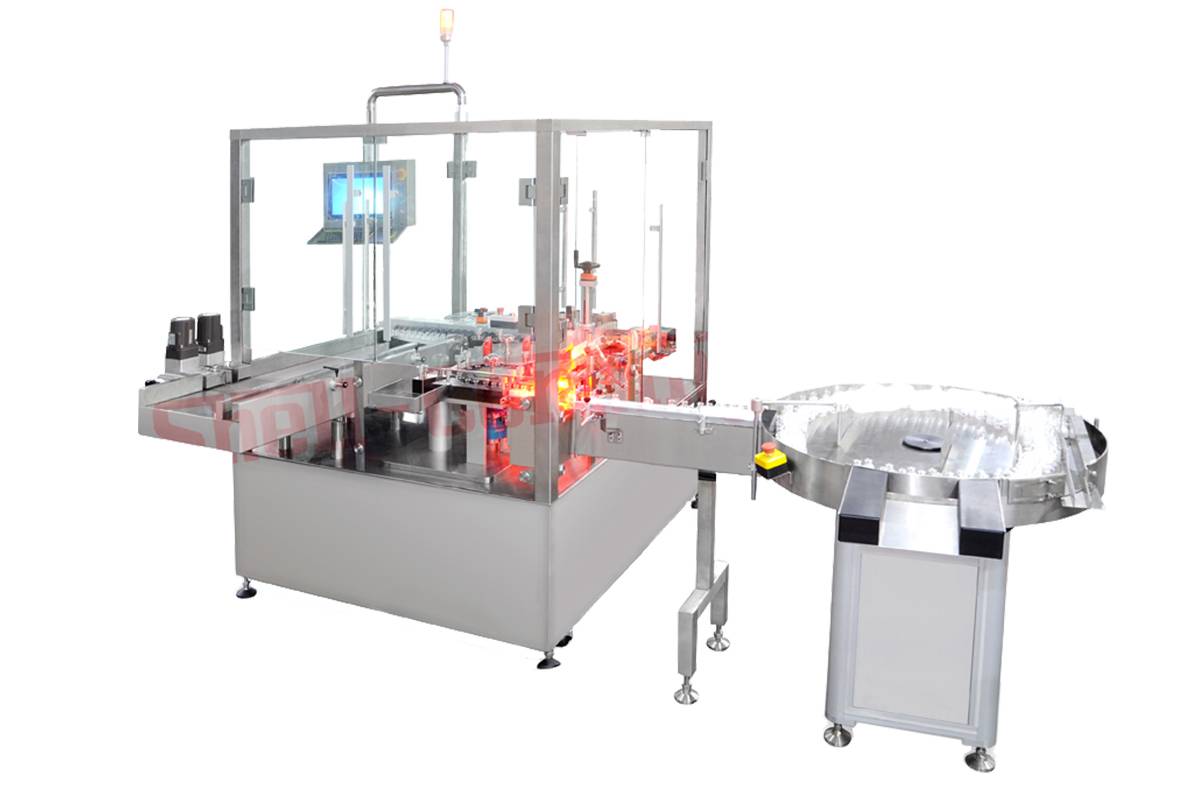

S308 High speed rotary vial labeling machine

Applicable to various types of schering (various kinds of ampoules. oral liquid bottles, vials etc), with diameter 10mm-30mm(or customized size)

The versatile S308 High Speed vial labeler medicine injection production line is armed with the newest and fastest netcon control technology(optional). With just a click of its one-touch screen, you can easily adjust the various settings for your product needs.

Performance features

- Adopting high-speed (Japan/France/U.S.A))servo labeling system;

- Applicable to various types of schering (various kinds of ampoules. oral liquid bottles, vials etc), with diameter 10mm-30mm(or customized size);

- High-precision labeling system, with labeling tolerance 1mm;-Stable speed: > 400 ~ 800 bottles/minute;

-Damage rate lower than 1/300,000;

- Intelligent control system to ensure no wrinkles when labeling and no air bubbles for transparent labels;

- Multi-intelligent inspection system, with perfect combinations of high-speed, precision, stability and reliability

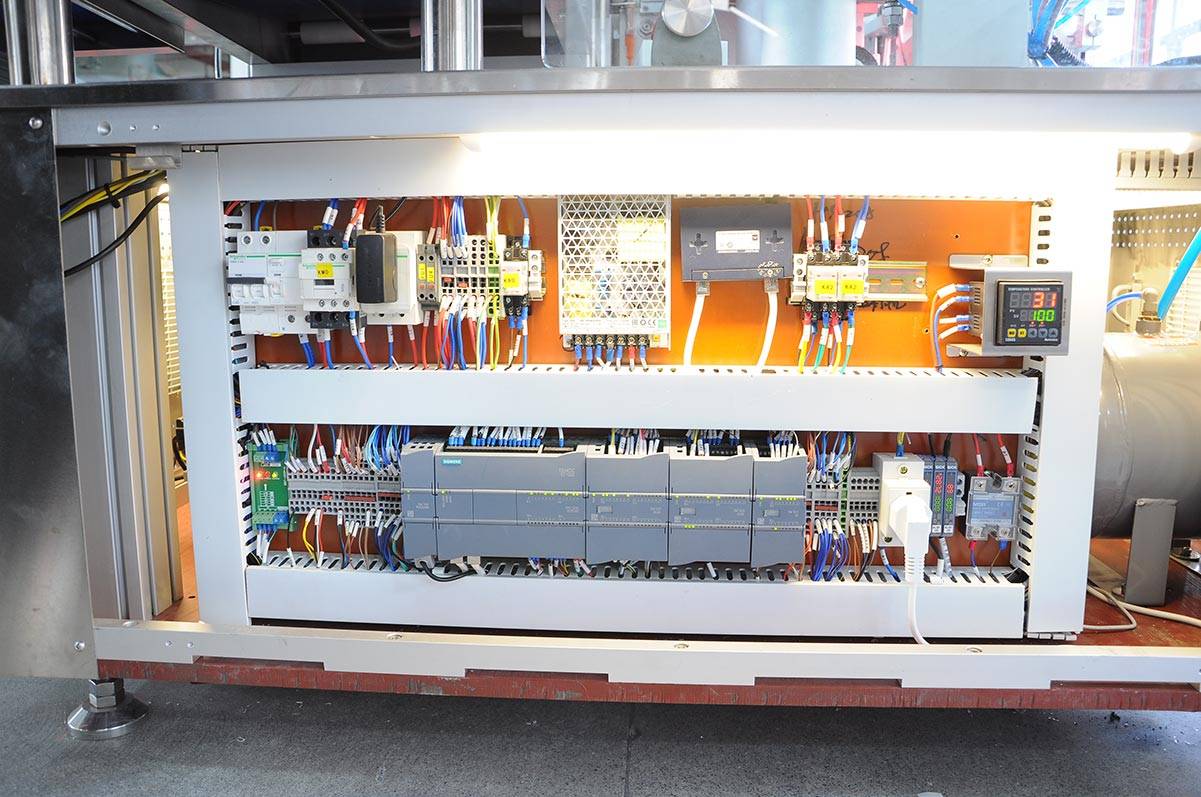

-The complete machine adopts SUS304 stainless steel and A6061

-High-strength aluminum alloy, with good appearance and compliance of the specifcation requirements of cGMP, FDA, OSHA, CSA, SGS and CE.

Optimal Configuration

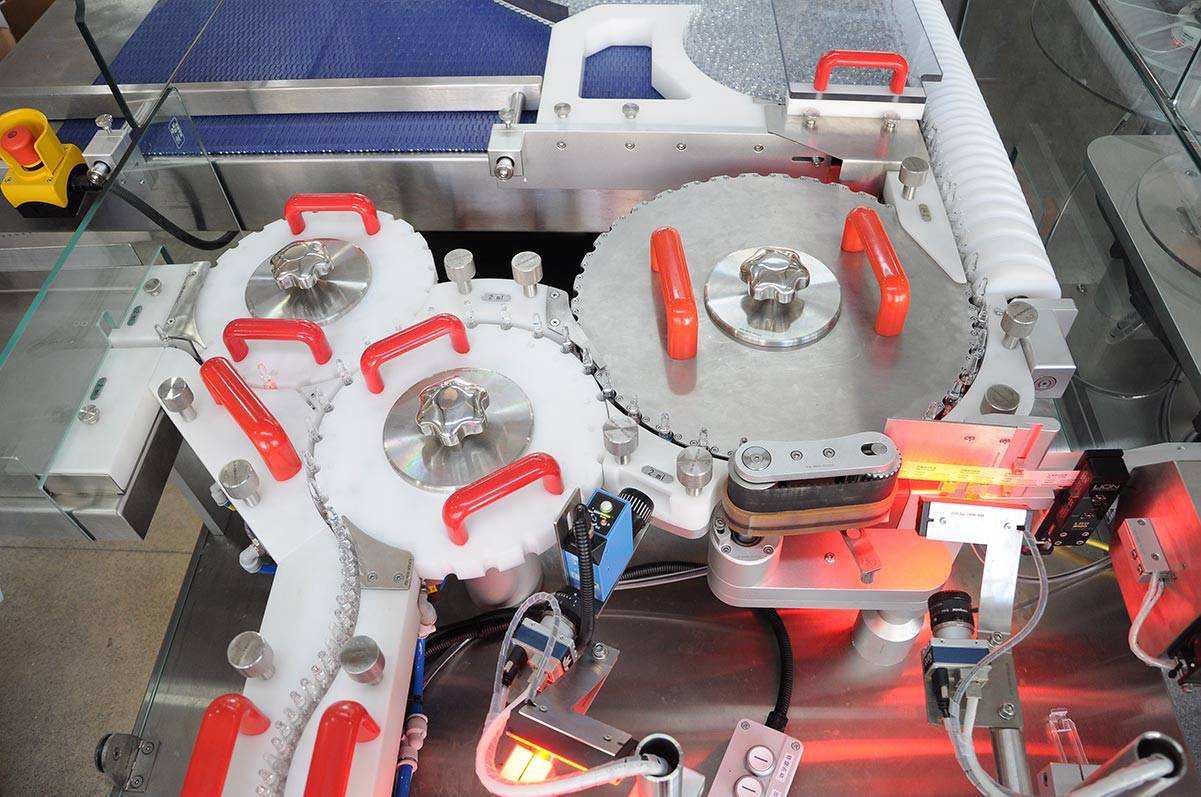

- Rotary & Roller turntable with three positioning to ensure accurate and stable high-speed labeling function;

- Stars wheeled reject device can accurately detect and eliminate errors orderly materials;when high-speed operating.

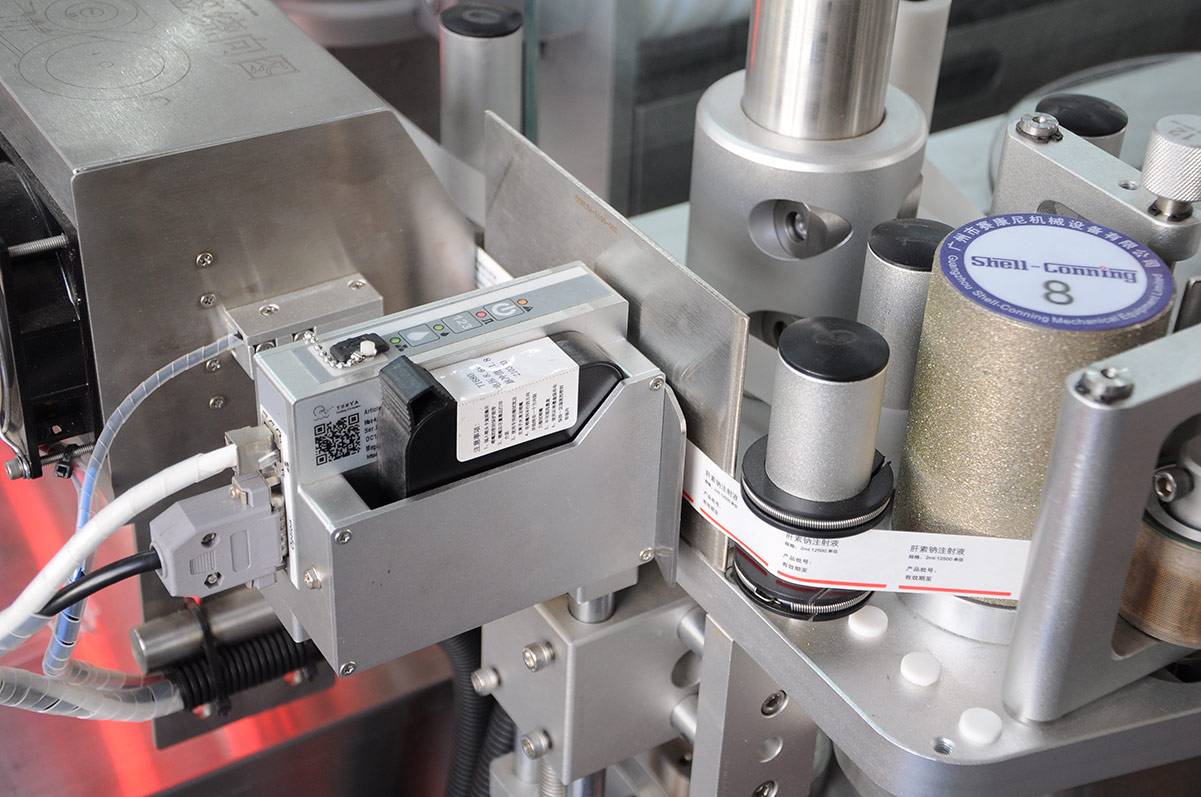

- Video detection device to provide a variety of detecting functions: Labeling detection, leak detection, and printing code detection,substandard goods will be removed and recycled

- Can choose high-speed hot stamping machine , thermal transfer printer or inkjet printing machine to realize coding synchronously;

- Supporting equipment running status and alarm information can be real-time reflect in the system.

Our machine with servo drivers deliver accurate and high speed repeatable labeling. An easily accessible hand wheel adjuster and side rail quickset adjuster allows more “up-time” on your production line! The S308 is used in virtually all industries such as pharmaceuticals, personal care products, foods, vitamins, cosmetics, and chemicals, where best-in-class reliability is the mandate for producing efficiently.

Maintenance is easy and efficient.

Sophisticated variable frequency drive controller ensure speed stability and ±0.5mm inaccuracy rate.

Guide rail portion of this vaccine injection production line is made with high quality aluminum covered with hard-wearing industrial plastic to ensure accurate labeling and product protection, keeping the customer’s product attractive and in perfect condition.

Labeler base is made of stainless steel to ensure full anti-rusting. This design ensures the machine and production space sanitation are maintained which is cater for GMP standards.

Wheels keep the machine portable, convenient when shifting to different production lines. This supportive mobile strength increases the value of your investment.

Specifications:

| Dimension | (L)2208 x (W)1420 x (H)1948mm |

| Container size | Φ10-30mm |

| Speed | ≤400-800bpm |

| Labeler accuracy | ± 0.5mm |

Product detail pictures:

Related Product Guide:

Our products are broadly identified and trustworthy by people and may meet continually modifying financial and social requires of Good Quality Pharmaceutical Machinery - S308 High speed rotary vial labeling machine – S-conning , The product will supply to all over the world, such as: Haiti, Albania, Uzbekistan, We set "be a creditable practitioner to achieve the continuous development and innovation" as our motto. We would like to share our experience with friends at home and abroad, as a way to create a bigger cake with our joint efforts. We have several experienced R & D persons and we welcome OEM orders.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.