Factory directly Commercial Bottle Labeling Machine - Plane Labeling Machine – S-conning Detail:

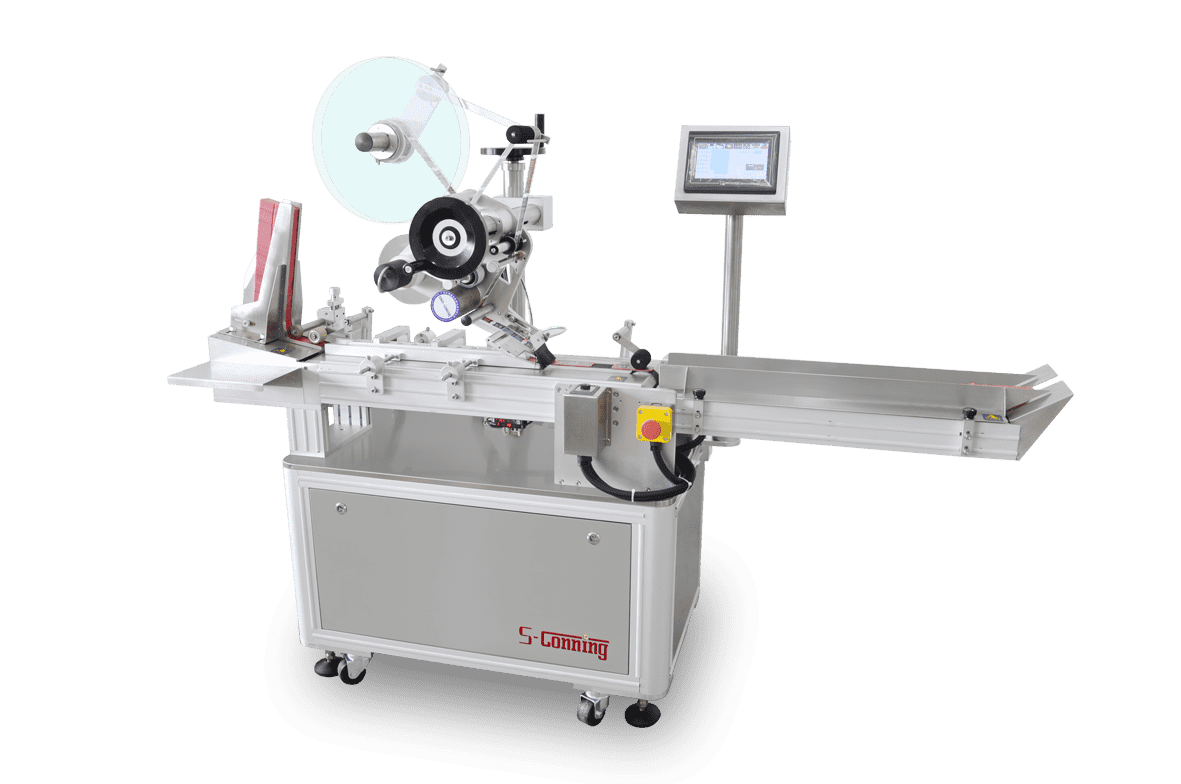

Plane Labeling Machine

S213 is an exquisitely designed automatic print and apply label systems and applicator in the range of daily cosmetic , electronic , pharmaceutical , foods & beverage other industries products.

The Optimal Upgrade

An independent reversely-rubbed feeder distributes flat items with various size and thickness smoothly and stably.

A vacuum suction conveyor leads to more stable and more accurate transport of products Print batch number, date, time, fixed data and so on in real time

Automatic feeding and labeling of flat objects such as fold-down cartons, leaflets,cads etc. Integrated options include online printing of variable information and barcodes/OR code, inspection and automatic rejection

-Vacuum assisted conveyor to ensure product stability during transport and labeling,and thus allows high operation speed of the system.

-Extra wide feeder and material path to cater for a wide range of product size.

innovational structure

Wide range adjustability suit for different size object. The unique pneumatic holding label mechanism , enhance the labeling precision.

sensible and flexible design convenient for different products labeling.

label applicator machine can plane labeling for different object, widen application range;

Premium Progress

*Can be connected with any automatic production line seamlessly

*Outstanding label feeding technology ensure the synchronous tension, position accuracy, no deviation when in batching, none breaking labeling when in high-speeding operation.

*Mature technology ensure no wrinkle and no air bubbles when labeling.

*Muti-intelligent inspection system perfect the high-speed, high precision, and stability.

*The complete labeling machinery adopt SUS304 stainless steel and high-strength aluminium alloy compliance with the cGMP, FDA, OSHA, CSA, SGS, and CE.

Features

From the design, very first time of operation, management, maintenance and the future production lines, S-conning think more for you and your company.

-Built in-operation manual: beginners can learn from the display on how to operate the machines within a short time. This saves both money and time during training.

Built in-troubleshooting manual: the display would guide the user through troubleshooting.

-User-friendly label length set up system: The up-to-day HMI controls allows the user to set label parameters.

-Control system of labeler utilizes a large touch screen panel, certified by CE and UL regulations for efficient and effective monitoring of the labeling process.

-This unique and innovative system can guarantee that label setting are programmed accurately and applied onto the proper position.

-Labeling counter-keeps tracks of the quantity of products processed by the machine.

-Pre-set counter - a quantity can be preset for a production batch and the machine will automatically stop as the amount is attained.

-Simply touching the screen allows you to delay label application and adjust label position.

Specification:

| Dimension | (L)2570 x (W)750x(H)1530mm |

| Container size | (W)40mm ~ 180 X (L)60~250 X (H)0. 3-2mm |

| Speed | ≤300pc/m |

| Labeler accuracy | ± 1.0mm |

Product detail pictures:

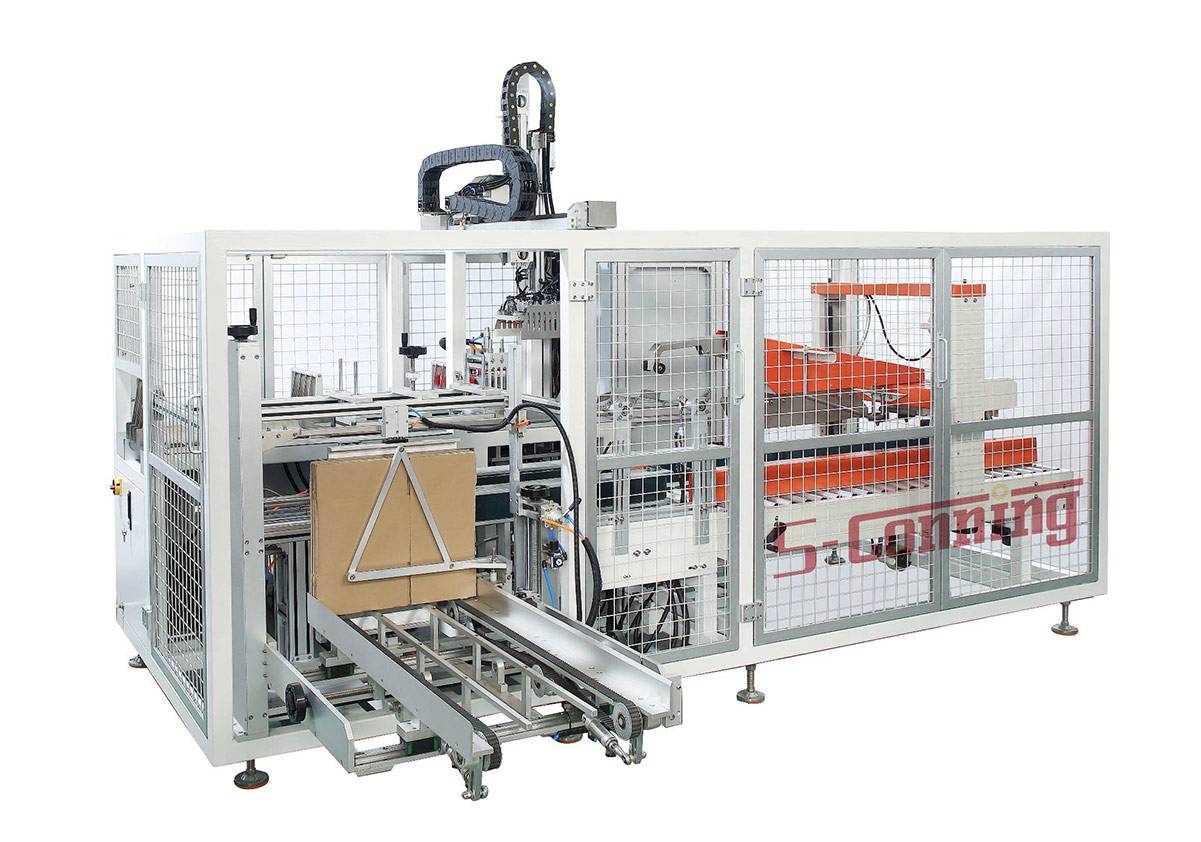

Related Product Guide:

We believe that long expression partnership is often a result of top of the range, value added service, prosperous encounter and personal contact for Factory directly Commercial Bottle Labeling Machine - Plane Labeling Machine – S-conning , The product will supply to all over the world, such as: Victoria, Singapore, Netherlands, Thus far, our item associated with printer dtg a4 may be shown in most foreign nations as well as urban centers, which are sought after simply by targeted traffic. We all highly imagine that now we have the full capacity to present you with contented merchandise. Desire to collect requests of your stuff and produce the long-term co-operation partnership. We very seriously promise:Csame top quality, better price; exact same selling price, higher quality.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!