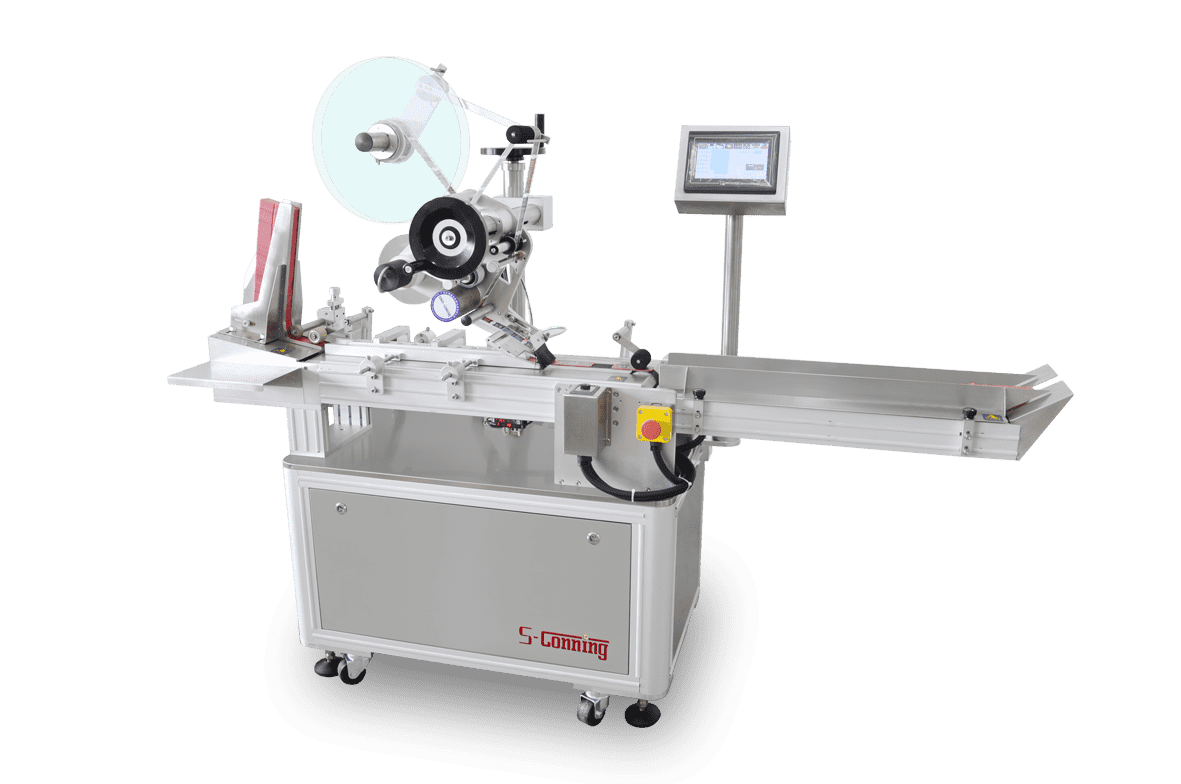

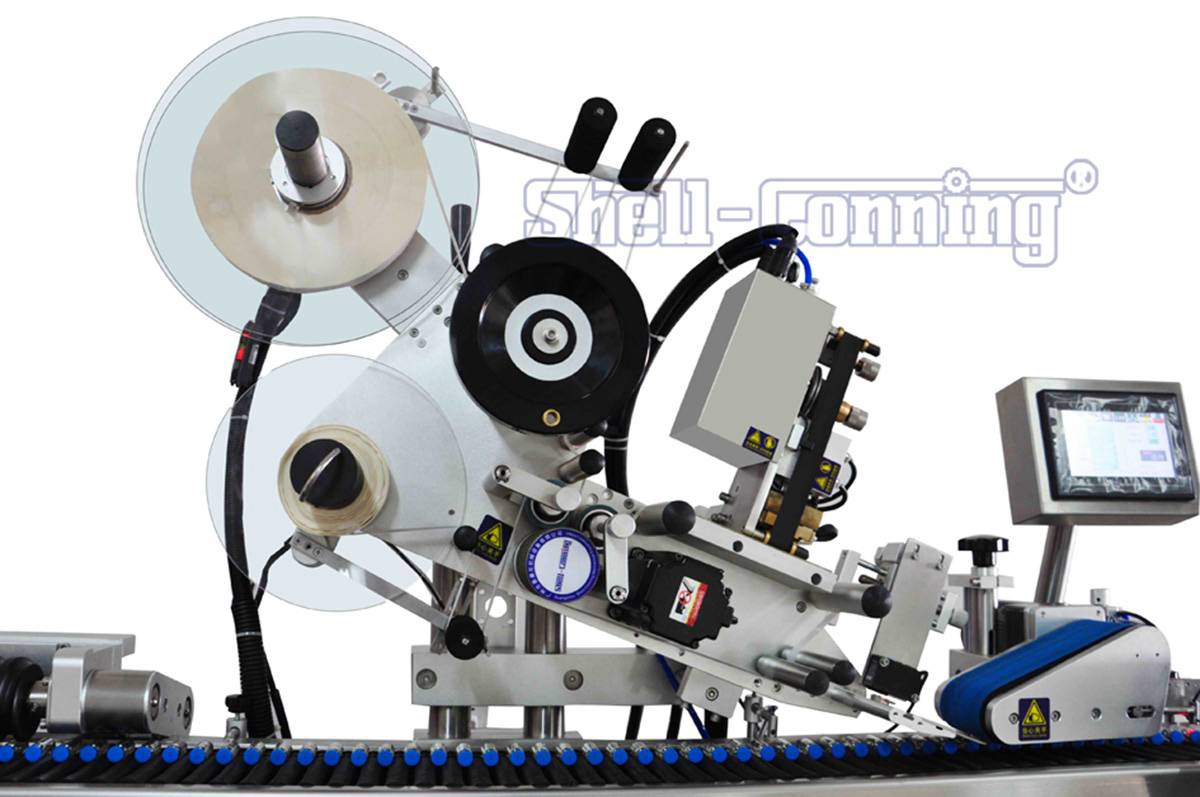

China Cheap price Pharmaceutical Liquid Filling Equipment – Automatic Horizontal Labeling and packing System – S-conning Detail:

S616

APPLICATION: An ideal high speed labeling solution and packing machine for the pharmaceutical industry.

-Applicable to various types of bottles, such as oral liquid bottles, ampoules, schering bottles and pen-injectors, etc.

practical production speed is up to 600 bottles per minute.

Performance features

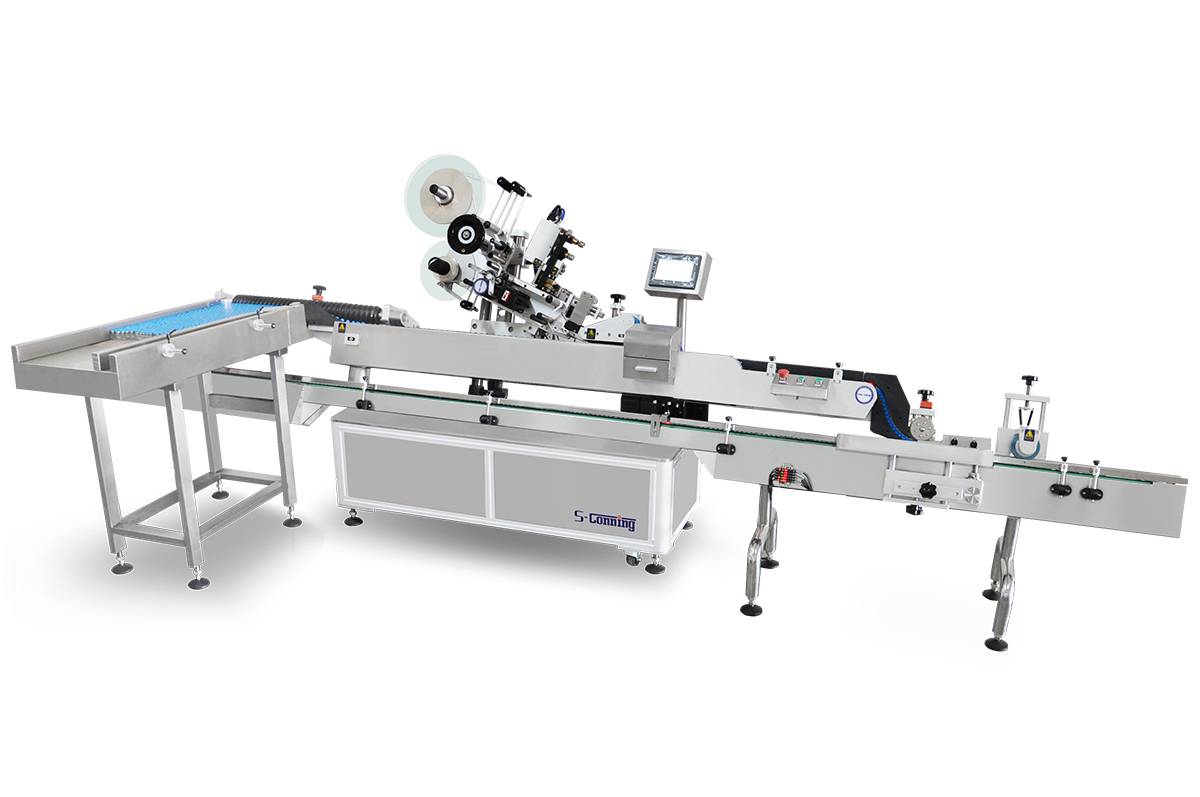

- integrated with labeling and tray insert and carton input(optional), the machine allows gang control, intelligent functions and high efficiency;

-Applicable to various types of bottles, such as oral liquid bottles,ampoules, schering bottles and pen-injectors, etc;

.Precision rate of input higher than 99.9%;.Stable speed of the whole line: about 500 bottles/minute;. Damage rate lower than 1/100,000;

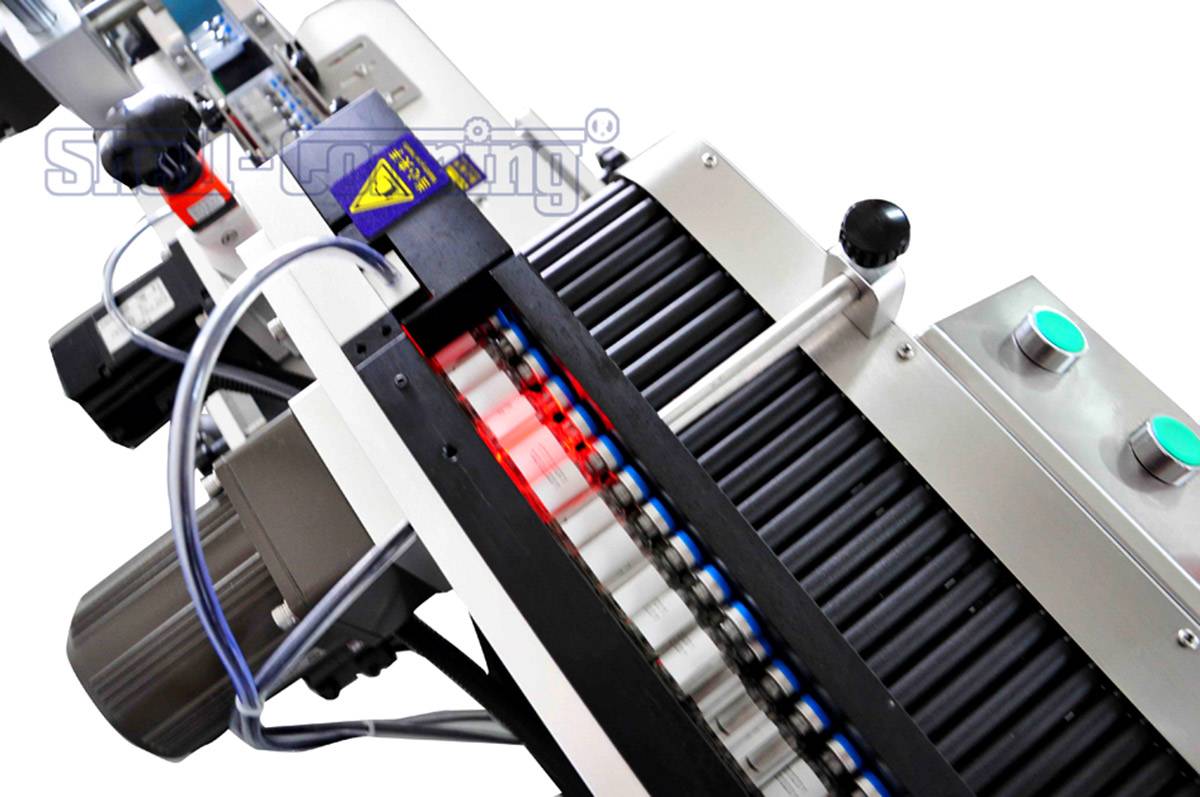

Interactive induction system for bottles input and transfer mechanism,to ensure accurate and stable input of bottle;

.The intelligent sensing technology is adopted to inspect the pushing force; the Teflon special process is applied on the rail surface of U buffer,ensuring no friction of bottle body, smooth carton input, no damages to the bottles and labels. The carton input is continuous and stable . No bottle no carton feeding, no carton no input of bottle;

.intelligent inspection system, with labeling speed automatic sensing and adjustment according to the supply condition of carton;

-The complete machine adopts SUS304 stainless steel and A6061

high-strength aluminum alloy, with good appearance and compliance of the specification requirements of cGMP, FDA, OSHA, CSA, SGS and CE.

We offer more than you need

① Container buffer magazine for tray inserting:Design of seamless connection makes labeled containers inserted into

the base tray more smoothly. The container buffer magazine has alarm for overload.

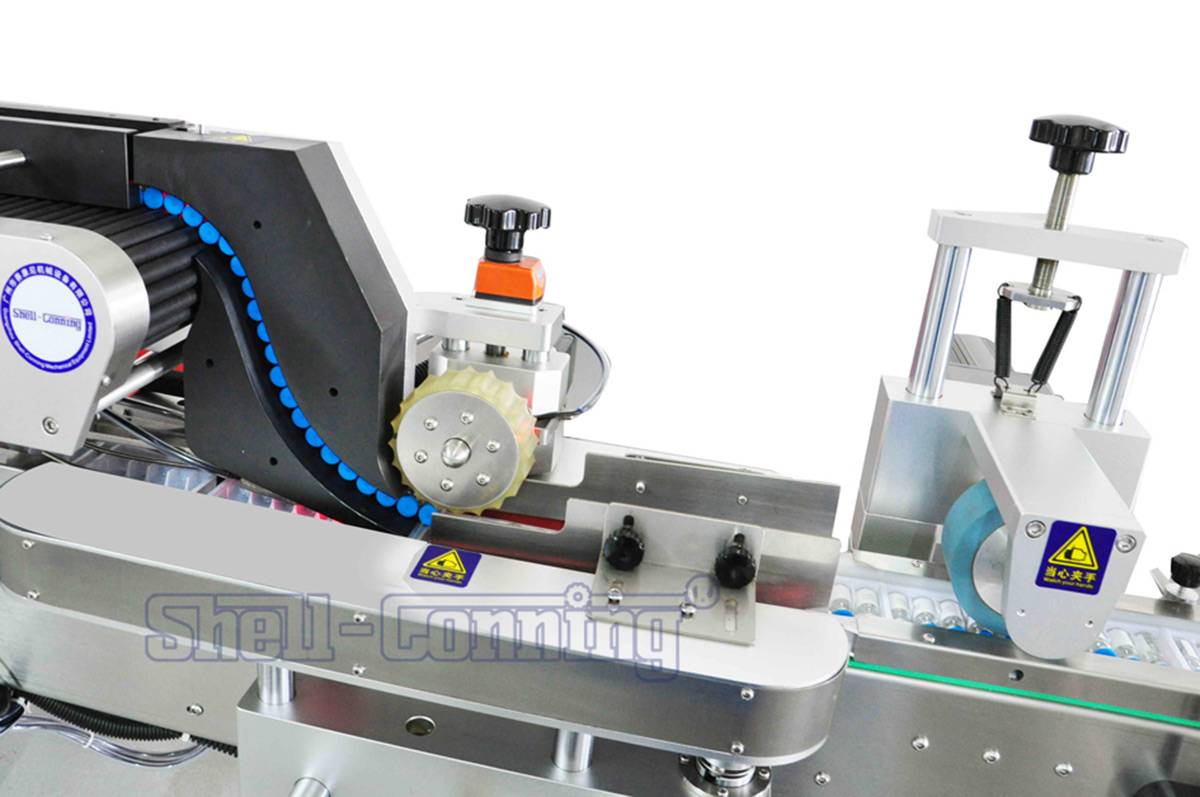

② Servo-driven mechanism for inserting containers into trays:Smooth discharge passage and discharging by gravity make

bottles move smoothly without resistance; a fully servo-driven roller fortray insertion makes the action more accurate.

③ Dynamic pressing mechanism:Inserting bottles into tray by its gravity makes the whole process perfect

Optimal Configuration

The versatile S616 High Speed Pharmaceutical Bottle packing line is armed with the newest and fastest netcon control technology(optional). With just a click of its one-touch screen, you can easily adjust the various settings for your product needs.

Our machine with servo drivers deliver accurate and high speed repeatable labeling. An easily accessible hand wheel adjuster and side rail quickset adjuster allows more “up-time” on your production line! The S921 is used in virtually all industries such as pharmaceuticals, personal care products, foods, vitamins, cosmetics, and chemicals, where best-in-class reliability is the mandate for producing efficiently.

Features

From the design, very first time of operation, management, maintenance and the future production lines, S-conning think more for you and your company.

-Built in-operation manual: beginners can learn from the display on how to operate the machines within a short time. This saves both money and time during training.

Built in-troubleshooting manual: the display would guide the user through troubleshooting.

-User-friendly label length set up system: The up-to-day HMI controls allows the user to set label parameters.

-Control system of labeler utilizes a large touch screen panel, certified by CE and UL regulations for efficient and effective monitoring of the labeling process.

-This unique and innovative system can guarantee that label setting are programmed accurately and applied onto the proper position.

-Labeling counter-keeps tracks of the quantity of products processed by the machine.

-Pre-set counter - a quantity can be preset for a production batch and the machine will automatically stop as the amount is attained.

-Simply touching the screen allows you to delay label application and adjust label position.

Specifications(for reference):

| Model | S606 S616 |

| Driving Mode | Simens PLC system |

| Yield(pcs/min) | 400~600BPM |

| Operating direction | Left or Right |

| Conveyor Speed(m/min) | ≤40 |

| Labeling Accuracy | ±0.5 mm |

| The inner diameter of label roll | 76 mm |

| The outer diameter of label roll | 350 mm(max) |

| The suitable label size | Can customized depends on client product |

| The suitable size of labeling objects | Can customized depends on client product |

| Printer use air | 5kg/cm ² |

| Voltage (In China) | AC220V 50/60HZ Single phase (Can customized as client need) |

| Power(w) | ABOUT 2.5KW |

| Weight(kg) | 500KGS |

| Machine size | 4000(L) 1600 (W) 1600 (H) mm |

Product detail pictures:

Related Product Guide:

We have now a skilled, performance group to offer excellent support for our consumer. We usually follow the tenet of customer-oriented, details-focused for China Cheap price Pharmaceutical Liquid Filling Equipment – Automatic Horizontal Labeling and packing System – S-conning , The product will supply to all over the world, such as: Orlando, Palestine, Florida, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.