Bottom price Soap Packaging Machine Manufacturer - High-speed automatic carton making and input production line – S-conning Detail:

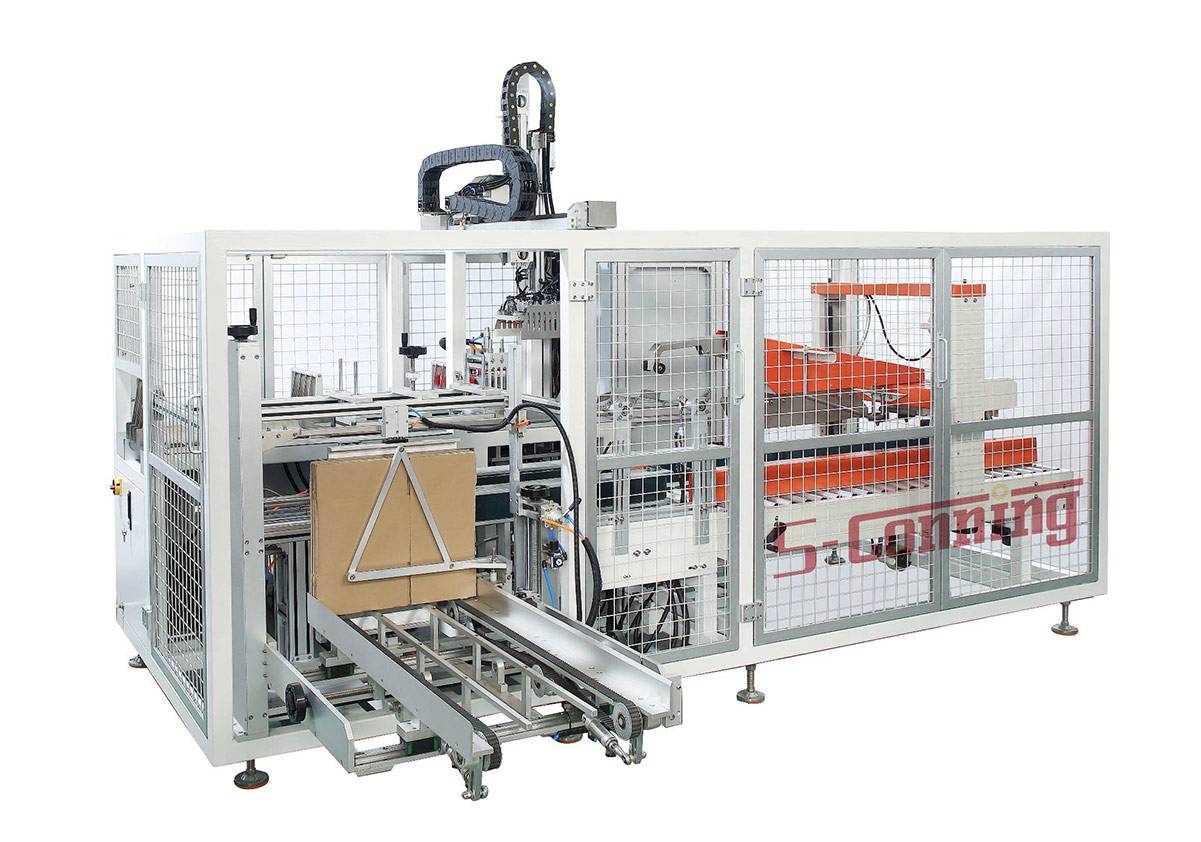

High-speed Automatic Carton Making & Input Production Line

APPLICATION:

This Fully Automatic Inter is the perfect combination of the S616 ZT384 and the Z130, enabling the highest production efficiency suitable for pharmaceutical, food, beverages, cosmetics, detergents, petrochemical industries and more. This packing labeling feeding tray making machine is your best choice for automatic production and label applicator machine for boxes.

The servo driven bottle packing machine price is designed for easy operations and quick changeover to different products. The machine can easily adjust based on customer’s product specification and requirements.

Advantages:

-Applicable to various types of bottles,such as oral liquid bottles, ampoules, schering bottles and pen-injectors, etc., with diameter smaller than25mm.

ampoules, schering bottles and pen-injectors, etc., with diameter smaller than25mm.

-The complete machine adopts servo labeling system and seal label, with perfect implementation of intelligent linkage of forming, carton input and punching.

-PVC film feeding is controlled by servo system, one forming for each feeding,with precise control and eliminated unstable factors caused by mechanical structure.

-The unqualified carton can be detected by the detection mechanism of carton forming unit to avoid being input into the carton.

-The large HMl touch screen provides abnormal information display and trouble-shooting guidance, as well as simple operation and convenient maintenance.The machine can easily used by anyone .

-By simply replacing the mold, the carton making and input mechanism canproduce cartons with all sizes according to customer’s needs.

-The unqualified carton can be detected by the detection mechanism of carton forming unit to avoid being input into the carton.

extra performance

• Easy to install and operate, requiring minimum maintenance for maximum performance and useful life.

• Integrated digital control with PLC and high tech touch screen controls for easy operation. All activities are controlled by the Panasonic servo system.

• Safety shield that meets strict safety regulations.

• Sturdy conveyer system driven by high quality motor. Adjustable conveyer guide rails to accommodate with different products.

• The unqualified carton can be detected by the detection mechanism Bottle jam detection.

• Adjustable electronic torque values to eliminate damage to packing and reduce insert wear.

Specifications:

1) .PLC combined with human/machine interface LCD touch screen controller.

2). Stainless steel frame construction and components are standard.

3). Labeling speed is automatically synchronized with conveyor speed to ensure quality labeling.

4). 50 Job Memory for easy recall.

5). Precision servo motor drive on label heads.

6).Ensure GMP environmental requirements.

7).Professional HMI touch screen: more humanized touch control screen

8).Label applicator be equipped with High quality servo motor

Specifications:

| Power Supply | AC380V 50/6 OHz 3山 |

| Total Power | 12KW |

| Punching Frequency | 20-30/Min |

| Atmospheric Pressure | 0.6-1.0 Mpa |

| Specfication Of bottle/tray size | Can Design As The Requirement Of Customer |

| Size (L) x (W) x (H) | 8090mmx3220mmx1786mm |

| Labeling Capacity | 60pcs/min (10bottles)/tray |

Product detail pictures:

Related Product Guide:

With dependable high quality approach, great reputation and excellent customer support, the series of products and solutions produced by our firm are exported to lots of countries and regions for Bottom price Soap Packaging Machine Manufacturer - High-speed automatic carton making and input production line – S-conning , The product will supply to all over the world, such as: Tunisia, Slovenia, Israel, Aiming to grow to be by far the most experienced supplier within this sector in Uganda, we keep researching on the creating procedure and raising the high quality of our principal merchandise. Till now, the merchandise list has been updated on a regular basis and attracted customers from around the globe. In depth data can be obtained in our web page and you'll be served with good quality consultant service by our after-sale team. They're about to make it possible for you to get complete acknowledge about our things and make a satisfied negotiation. Small business check out to our factory in Uganda can also be welcome at any time. Hope to obtain your inquiries to get a happy co-operation.

The factory has advanced equipment, experienced staffs and good management level, so product quality had assurance, this cooperation is very relaxed and happy!